Need some assistance?

- Overview

-

By Type

Custom - Standard (AS568)

-

By Brand

Parker - Freudenberg

-

By Material

Nitrile - FKM

- EPDM

- FFKM

- Silicone

- Fluorosilicone

- PTFE

- Polyurethane

- Teflon Encapsulated

- HNBR

- Overview

-

By Type

U-Cups - Wipers

- Wear Rings

Need some assistance?

Need some assistance?

-

O-RINGS

- Overview

-

By Type

Custom - Standard (AS568)

-

By Brand

Parker - Freudenberg

-

By Material

Nitrile - FKM

- EPDM

- FFKM

- Silicone

- Fluorosilicone

- PTFE

- Polyurethane

- Teflon Encapsulated

- HNBR

-

HYDRAULICS & PNEUMATICS

- Overview

-

By Type

U-Cups - Wipers

- Wear Rings

- ROTARY SEALS

- CUSTOM MOLDED

- GASKETS

- MACHINED RUBBER & PLASTICS

- EXTRUDED SHAPES & PROFILES

- SPECIALTY PRODUCTS

Wiper Seals

HYDRAULICS & PNEUMATICS

Understanding the integral role that various seal types play in the functioning of different systems and industries is key for engineers who prioritize quality and reliability. One such crucial component is the wiper seal. This piece serves a distinctive purpose within a range of systems, demonstrating its value in a multitude of applications.

In this guide, our seal experts will teach you what wiper seals are, illuminate the benefits of their use, and identify some applications they are commonly used in.

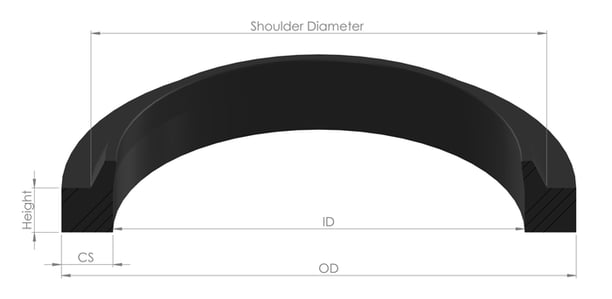

What Are Wiper Seals?

Wiper seals, sometimes referred to as scraper seals, are installed in hydraulic and pneumatic cylinders to scrape off any particulate, debris, or moisture that may cling to the rod as it retracts into the system. By cleaning the rod, these seals prevent contaminants from entering the hydraulic or pneumatic system, protecting it from potential damage and ensuring optimal functioning.

Wiper Seals Material Description

Wiper seals are commonly constructed from robust materials like polyurethane, nitrile rubber (NBR), or fluorocarbon elastomers (FKM), chosen for their impressive durability, abrasion resistance, and resilience to a variety of conditions.

Polyurethane wiper seals offer exceptional mechanical properties, exhibiting high tensile strength and outstanding tear and abrasion resistance. Nitrile rubber, on the other hand, offers excellent oil and fuel resistance, making it suitable for applications involving oil-based hydraulic fluids. Lastly, FKM wiper seals are prized for their resistance to extreme temperatures and chemicals, perfect for demanding applications.

Benefits of Wiper Seals

The primary advantage of wiper seals lies in their protective function. By preventing contaminants from entering the hydraulic or pneumatic system, they prolong its lifespan, enhance efficiency, and reduce the likelihood of costly and inconvenient system failures. They also contribute to maintaining the cleanliness of the work environment and reduce the amount of time and resources spent on maintenance and cleaning.

Common Uses and Applications

To better understand wiper seals, here are some specific scenarios where they are commonly used.

Construction Equipment

Wiper seals are crucial in heavy machinery like excavators and cranes, where they prevent dirt, debris, and weather elements from infiltrating hydraulic and pneumatic systems.

Industrial Machinery

In applications such as hydraulic presses or injection molding machines, wiper seals maintain system integrity by keeping abrasive particles out, ensuring consistent performance and prolonging equipment life.

Automotive

Within vehicle braking systems, wiper seals prevent contaminant ingress, contributing to safety and reliability.

Aerospace

In applications like aircraft landing gear and control systems, wiper seals help maintain system cleanliness, ensuring reliable, safe operation.

Agricultural Machinery

In equipment such as tractors and harvesters, wiper seals keep out dirt, plant matter, and other debris, reducing wear and preventing system failure.

Things to Consider When Selecting Wiper Seals

When choosing wiper seals from Wyatt Seal, the obvious factors such as cost, size, and material compatibility with your system are important. However, other factors are worth considering too, such as:

- Operating Environment: The surrounding conditions can heavily influence the longevity and effectiveness of your wiper seal. In dirty or gritty environments, a more robust and abrasion-resistant material may be required.

- Temperature Range: Consider the temperature range the seal will be subjected to. For extreme temperatures, certain materials like FKM may be more suitable.

- Chemical Compatibility: The seal material should be compatible with hydraulic fluids and resistant to any chemicals it may come in contact with.

- Maintenance and Replacement: Consider the frequency of seal replacement in relation to machine service intervals to optimize productivity and maintenance costs.

Find the Right Wiper Seal for Your Application

Wiper seals are essential to the health and longevity of hydraulic and pneumatic systems in a myriad of applications. By maintaining the cleanliness and integrity of these systems, they provide benefits that extend beyond cost savings to include enhanced system reliability and operational safety. For engineers seeking the highest quality, Wyatt Seal is the go-to choice for wiper seals. With a wide range of options and expertise in sealing solutions, we can provide the ideal wiper seal for your specific needs. Trust our team to be your partner in maintaining the health and efficiency of your hydraulic and pneumatic systems. Looking to find the right wiper seal for your application? Let’s talk.