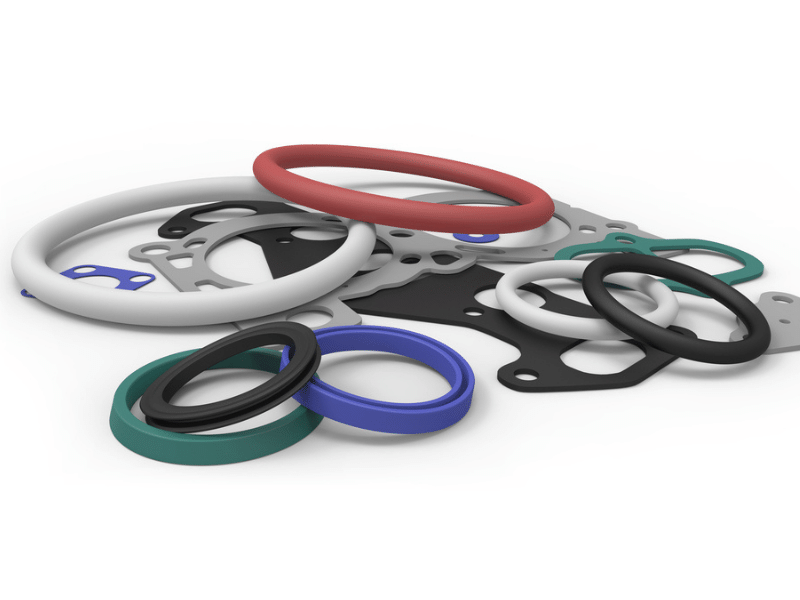

Seals serve as essential components across various industries, ensuring containment, preventing leaks, and maintaining operational efficiency. However, their effectiveness can be compromised by a range of defects, each with its own set of consequences.

Wyatt Seal Blog

In response to the imperative to reduce greenhouse gas emissions, Carbon Capture Utilization and Storage (CCUS) has emerged as a vital solution. CCUS technologies offer the potential to capture and store carbon dioxide (CO2) emissions from industrial sources, preventing their release into the atmosphere.

Learn how to select the perfect seal based on pressure dynamics related to the environment, material properties, and testing best practices to ensure optimal performance.

This guide simplifies seal selection by focusing on chemical compatibility. It considers media types, environmental factors, application types, temperature, and pressure impact. It's a helpful resource to ensure you find the right seal for any application.

Understand the importance of temperature ranges, media, application type, and pressure in seal performance and durability to choose the right O-ring. This guide will help you select the ideal material for your specific needs, ensuring optimal functionality.

Industrial O-rings function as seals between mechanized parts that carry pressurized gases or liquids, performing optimally under defined use conditions while inhibiting leaks. Using inappropriate materials can render the seal brittle or prone to leaks under certain chemical, temperature, friction, or pressure conditions. Learn about 5 common industrial O-ring materials in this informative blog article from Wyatt Seal.

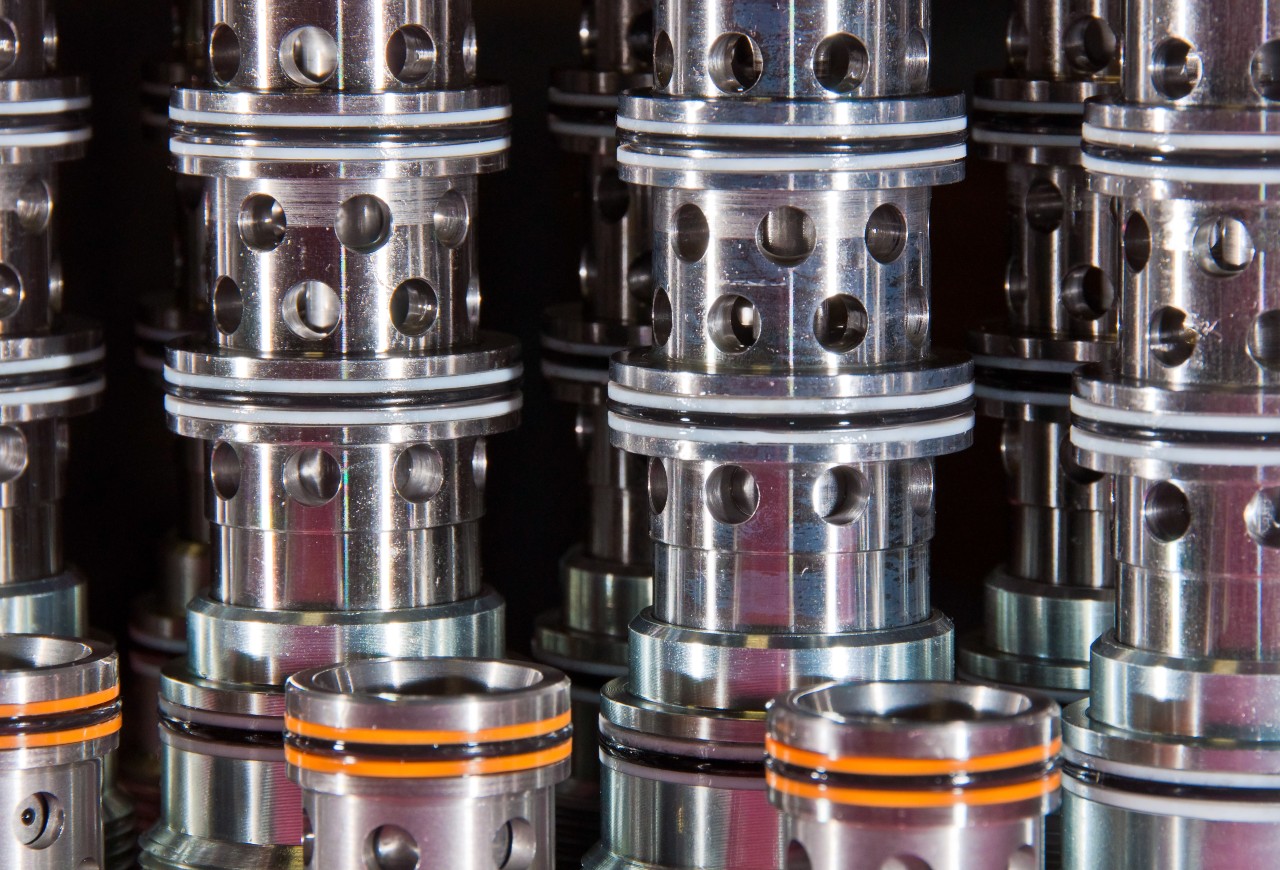

Uniquely formulated polyurethane for high-performance hydraulic sealing with maximum durability. Industrial seals are often used when other sealing materials can’t meet performance standards under harsh conditions such as very high temperatures, high vibration, or exposure to solvents or other chemicals.

Finding or designing seals for a specific application can be daunting, especially in specialty applications where performance matters most and failure is not an option. That’s where Finite Element Analysis (FEA) can help you save valuable time and money in your search.

When looking for an O-ring, there are many different materials out there. Viton® and nitrile are two of the most common materials used to create O-rings, and for a good reason. Both have excellent properties, a good compression set, and varied chemical resistances. So which material is suitable for your application?

The shelf life for industrial seals varies among different materials. Discover this guide on why shelf life matters and which materials have specific shelf lives.