Hydraulic seals play a crucial role in industries by stopping leaks, keeping pressure steady, and making machines last longer, all while being cost-effective and boosting safety.

Fluid Containment

Hydraulic seals are engineered to block or separate fluids in reciprocating motion applications. They create a barrier that prevents leaks and ensures the fluid remains contained within the hydraulic system. This containment is crucial for maintaining the efficiency and safety of machinery.

Conversion of Power

Hydraulic seals play a pivotal role in converting fluid power into linear motion. This conversion is at the heart of many industrial processes, enabling the controlled movement of components like cylinders and pistons. Without reliable seals, the fluid power would dissipate, rendering the machinery ineffective.

Maintenance of Pressure

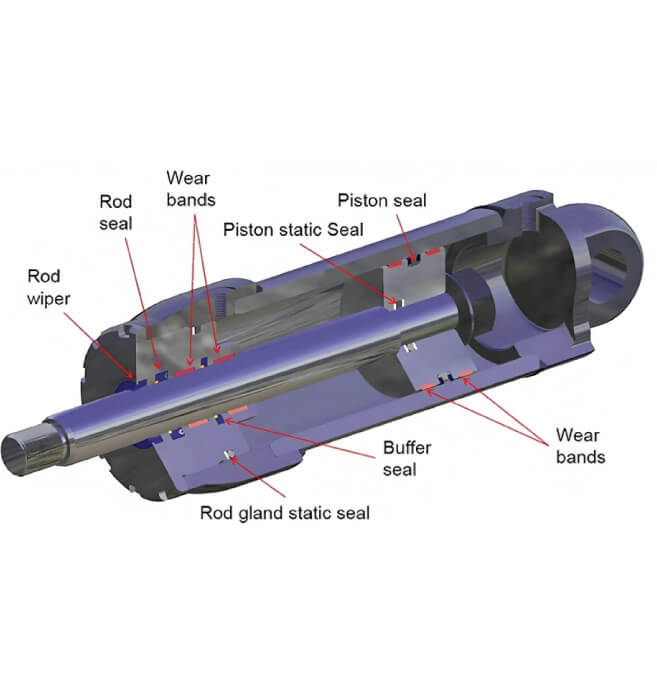

Hydraulic systems often operate at high pressures. Hydraulic seals, including rod seals and piston seals, are designed to maintain these pressures within the system. Without effective sealing, pressure loss can occur, leading to reduced system performance and potential safety hazards.

Longevity and Reliability

Hydraulic seals are known for their durability and long operating life. They are designed to withstand the rigors of industrial applications, including exposure to extreme temperatures, high pressures, and continuous movement. Their resilience reduces maintenance requirements and enhances overall system reliability.

Cost-Effective Solution

By preventing fluid leaks and maintaining system efficiency, hydraulic seals contribute to cost savings in the long run. Reduced downtime, lower maintenance costs, and improved equipment lifespan all add up to a more cost-effective operation.

Safety

Hydraulic seals enhance safety by minimizing the risk of hydraulic fluid leaks, which can pose safety hazards in the workplace. By containing the fluid and preventing it from escaping, hydraulic seals help create a safer working environment for operators and maintenance personnel.

Environmental Protection

In addition to preventing fluid leakage, hydraulic seals also contribute to environmental protection. They help ensure that hydraulic fluid stays within the system, preventing contamination of the surrounding environment. This is especially critical in applications where fluid leaks could have adverse effects.

Versatility

Hydraulic seals are available in various materials, such as polyurethane, rubber, and PTFE. This versatility allows for the selection of the most suitable material based on specific operating conditions, including fluid type, pressure, chemical compatibility, and temperature. This adaptability ensures optimal performance and longevity.