Not all O-rings are created equal when it comes to O-ring shelf life, as materials deteriorate at different rates. O-rings play an essential role in many types of equipment, and they may fail if the seals are not stored properly or past their useful lifespan.

Wyatt Seal Blog

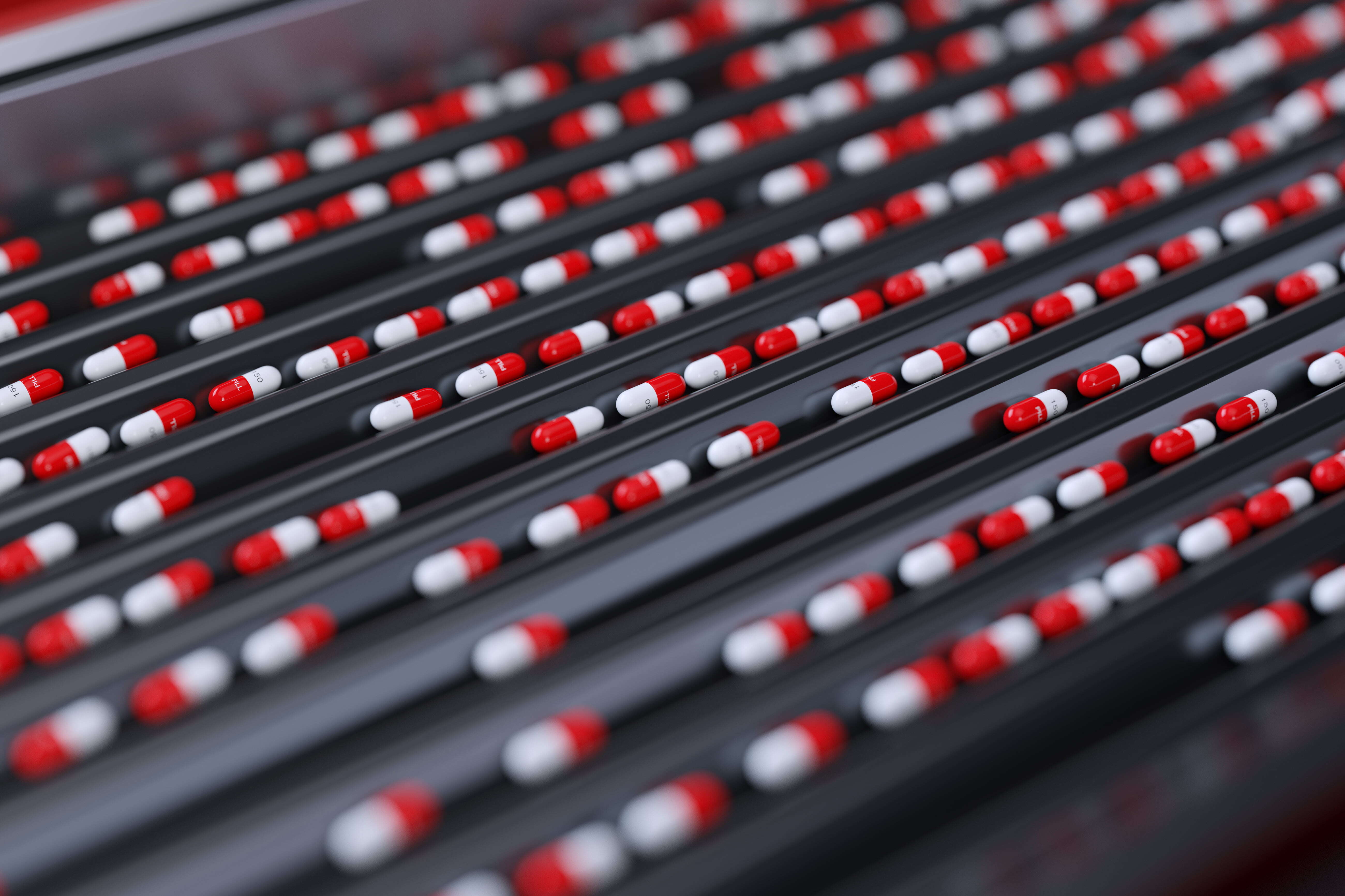

In pharmaceutical manufacturing, maintaining product integrity, preventing contamination, and ensuring compliance with regulations are top priorities.

Here's a detailed guide on how temperature range, pressure, and fluids and viscosity specifications will dictate the type of industrial seal you need.

Metal detectable O-rings are essential for maintaining safety in the food and beverage industry’s production processes. Combining rubber and metal fillers, these innovative seals ensure that any contamination caused by seal degradation is quickly identified using metal detectors or X-ray scanners.

When it comes to sealing solutions, choosing the right O-ring is critical, and one of the most important factors to consider is shore hardness. But what exactly does this term mean for your project?

At Wyatt Seal, we are proud to offer a range of high-quality Parker Hannifin metal seals designed to meet the most demanding sealing requirements. These seals are engineered to perform under extreme conditions, providing reliable solutions for applications where traditional elastomeric seals might not suffice.

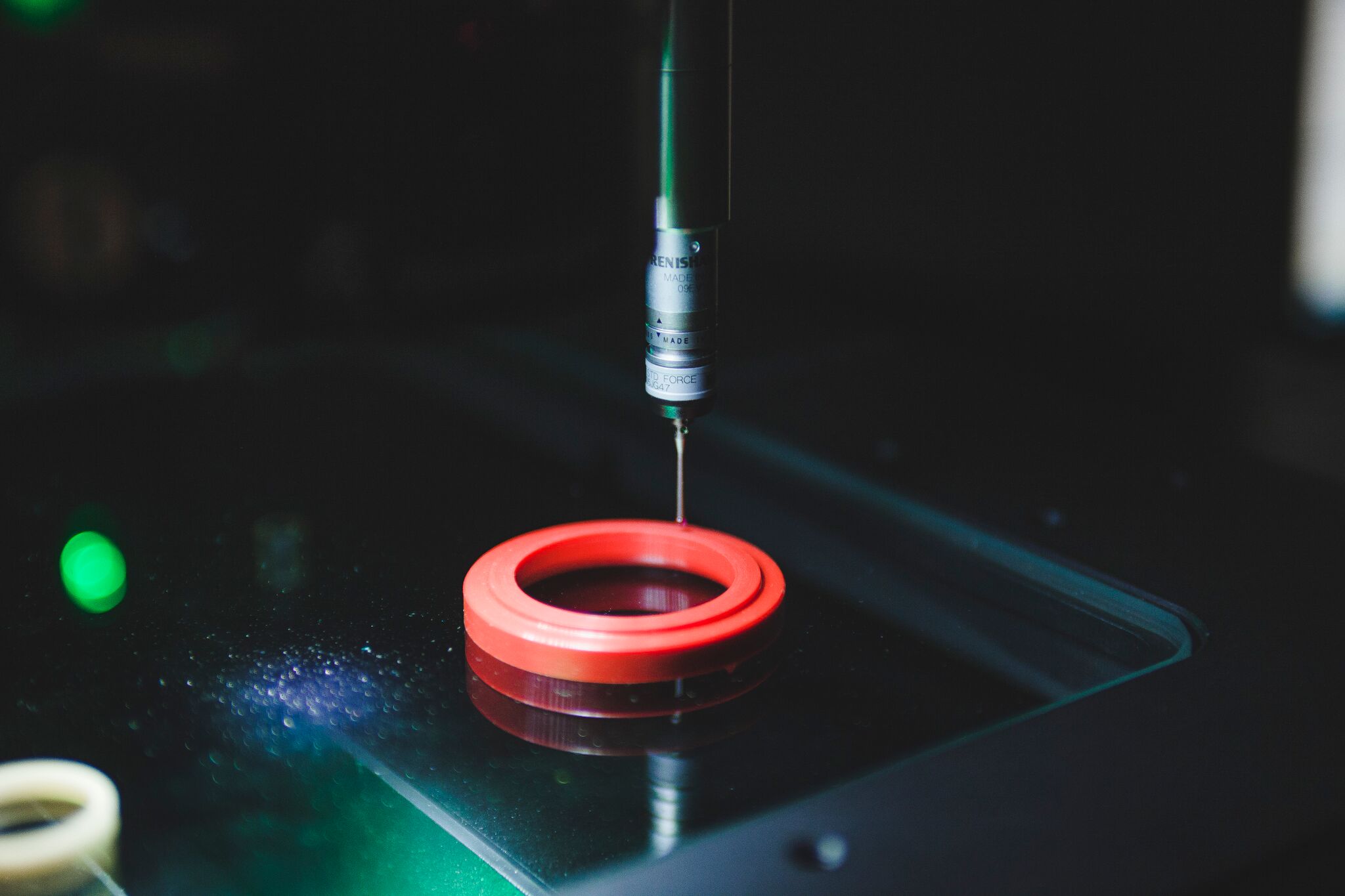

Deciding between a standard seal and a custom seal involves several considerations that relate directly to your specific needs and the demands of your application.

When designing fluid containment systems, the comprehension of both face seals and radial seals holds significant importance.

When an O-ring is said to be “food grade,” it’s understood to meet a rigorous standard of quality and cleanliness.

Food production is subject to stringent regulations to ensure safety and quality standards are met. Within this highly regulated industry, industrial seals play a critical role in maintaining the integrity of food processing operations.